An overview on common wastewater treatment technologies

In the development of science and technology, Water purification technology, in general, and wastewater treatment technologies, in p articular, are constantly improving with superior technologies to help treat and clean the environment. The following is a summary of wastewater treatment technologies that are widely applied today:

1. Course treatment by simple mechanical methods

Industrial wastewater, as well as domestic wastewater often contains dissolved and insoluble substances in the form of suspended particles. The suspended impurities can be solid and liquid, forming a suspension with water.

To separate trash and suspended particles from wastewater, mechanical processes (interrupted or continuous) are usually used: filter through bars or mesh, settle under the effect of gravity or centrifugal force and filtration. The choice of treatment method depends on the particles, physical, and chemical properties, suspended particle concentration, wastewater flow and required cleaning level.

Mechanical treatment is a method aimed at removing and separating insoluble substances and colloidal substances from wastewater. The treatment works include:

• The trash rack/screen (coarse net) is operated manually

• Trash rack/screen (fine filter net) operates automatically

• Air conditioning tank stabilizes the flow

• First phase sedimentation tank and 2nd phase sedimentation tank separate suspended sediments.

Mechanical treatment can remove up to 60% of insoluble impurities and reduce pollutants capable of biodegradable (BOD) up to 20%

1.1. Filter through screens or nets

This is a preliminary treatment. The purpose of the process is to remove all the objects present in the wastewater that can cause problems in the operation of the wastewater system such as clogging pumps, pipes, or canals. This is an important step in ensuring safety and creating favorable conditions for the whole system. I.2.1.1 Garbage Barrier Wastewater transported to cleaning works must first pass-through trash rack. At the trash rack, raw impurities such as trash, nylon bags, fruit peels, rags, wood, and other objects are retained to ensure stable operation of pumps and wastewater treatment facilities. This is an important step to guarantee the safety of the entire wastewater treatment system.

Figure 1. A self-cleaning mechanism is built into the raw trash screen (garbage screen)

1.2. Trash screen (garbage screen)

Wastewater brought to cleaning works must first pass-through trash screen. At the trash screen, raw impurities such as trash, nylon bags, fruit peels, rags, wood, and other objects are retained to ensure stable operation of pumps and wastewater treatment facilities. This is a critical step in ensuring the overall safety of the wastewater treatment system.

Based on the distance between the barriers, trash cans can be divided into categories such as: The coarse trash rack has a 60-100 mm distance between the bars, while the fine trash rack has a distance between the bars of 10-25 mm. Trash bars are made of metal, cleaned manually or mechanically and set at an angle of 45 - 600. The velocity of water flowing through the trash rack is limited in the range of 0.6 - 1 m/s. The maximum speed fluctuates in the range of 0.75 - 1 m / s to avoid pushing garbage through the cleft of the trash rack and the minimum speed through the slot is 0.4 m / s to avoid the decomposition of solids.

Figure 2. The fine trash filter has an automatic cleaning mechanism

1.3. Coarse Net

Wastewater brought to cleaning works must first pass-through trash rack. Trash screen can be placed permanently or mobile. It can also be combined with the garbage mill. The most common are the fixed guard bars. It made of metal placed at the inlet of the channel. The bars can also be circular, square, or mixed.

1.4. Fine Filter Net

To remove small suspended solid, a fine filter net with a pore sizes of 0.5 - 1 mm is often used.

2. Wastewater treatment by physiochemical technologies

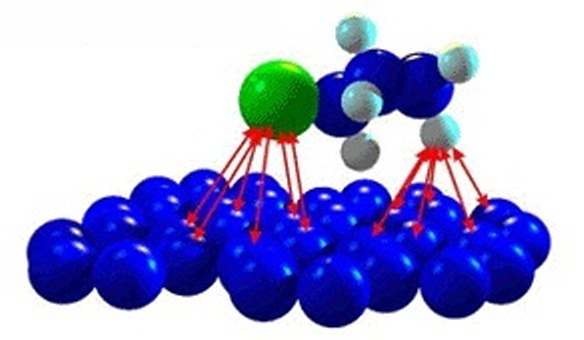

2.1. Adsorption technology in wastewater treatment

Adsorption method is widely used to thoroughly clean wastewater from dissolved organic substances after biological treatment as well as local treatment when the wastewater contains a very small amount of these substances. These substances are not biodegradable and are often highly toxic. If the substances which should be cleaned up are well absorbed and when the specific cost of the adsorbent is not large, the application of this method is most reasonable..

Figure 3. London dispersion force (plays a major role in the adsorption process)

In the general case, the adsorption process consists of 3 phases:

- Move substances which need to be adsorbed from the wastewater to the surface of the adsorbent

- Perform the adsorption procedure

- Move contaminants into adsorbent particles (inner diffuse zone)

People often use activated carbon, synthetic substances, or some manufacturing waste such as ash, slag, iron filings and mineral adsorbents such as clay, silica. To remove pollutants such as surfactants, synthetic colorants, chlorinated solvents, phenol and hydroxyl derivatives…

Application of the adsorption process

• Separation of organic solid such as phenols, alkylbenzen-sulphonic acids, dyes, and aromatic compounds from wastewater with activated carbon

• Activated carbon can be used to remove mercury

• It can be used to separate persistent dyes

• The application is limited due to the high cost

Figure 4. Integrated ion exchange & adsorption system

2.2. Wastewater treatment by ion exchange technology

Ion exchange method is used to purify water or wastewater from metals such as Zn, Cu, Cr, Ni, Pb, Hg, Cd, Mn … as well as arsenic, phosphorus, cyanide, and radioactive compounds. This method allows for the recovery of substances and a high level of cleaning. Therefore it is a widely used method for salt separation in water and wastewater treatment. The essence of ion exchange is a process in which ions on the surface of a solid exchange with ions of the same charge in solution when in contact with each other. These substances are called ionites (ion exchangers), they are completely insoluble in water. Ion exchangers that are able to exchange positive ions from electrolyte solutions are called cationites and are acidic. Substances that are exchangeable with negative ions are called anionides and they are alkaline. If certain ions exchange both cations and anions, they are called hermaphrodite ions. Ion exchangers can be either naturally occurring organic or synthetic organic or inorganic substances.

Application of ion exchange processes

• Water softening: An important application of ion exchange is to soften water, in which ions Ca2+ và Mg2+ are separated from water and replace Na+ position in the resin. For water softening processes, strong acid ion exchangers with Na+ are used.

• Demineralization: during demineralization, all negative and positive ions are removed from the water. The water moves through a two-stage system consisting of a series of strong acid cation exchangers in the H+ form with a strong base anionic exchanger in the OH - form.

• Ammonium reduction (NH4+): Ion exchange can be used to concentrate NH4+ present in wastewater. In this case, a highly selective NH4+ metabolite such as clinoptilolite must be used. After regeneration, the concentrated solution can be processed into feces.

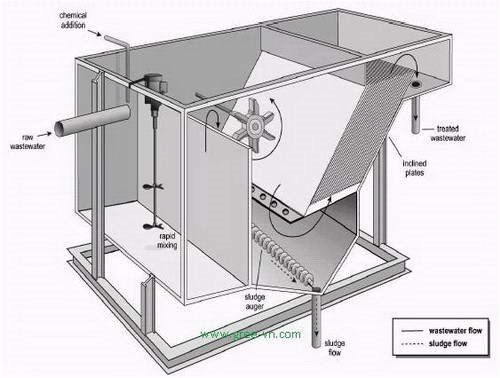

2.3. Flocculation process

Wastewater insoluble or insoluble sludge particles are often varied in type and size, and can include particles of sand, clay, humus, microorganisms, decomposable organic products… Particle sizes can range from a few micrometres to several millimeters. Only particles larger than 1 mm in size can be removed by mechanical (physical) treatments.

For particles less than 1 mm in size, if the sedimentation process is used, it takes a very long time and it is difficult to achieve high treatment efficiency, so it is necessary to apply physicochemical treatment.

Figure 5. Flocculation system combined with lamella sedimentation

The purpose of the flocculation process is to separate particles of the size 0.001 (m <(<1 (m)), which cannot be separated by conventional physical processes such as sedimentation, filtration or flotation. The process includes:

• The process of compressing the double charged layer, reducing the zeta electric potential is due to the opposite ion: when adding opposite ions to the wastewater with a high concentration, the ions will move to the diffusion layer into the double charged layer and increase. charge in the double charged layer, reducing the zeta electrodynamic potential and reducing the electrostatic force.

• A zero-zeta isoelectric point is generated by the flocculation process, which neutralizes the charge by opposite ion adsorption on the surface. In this case, adsorption is the most critical aspect.

• Bridging mechanism for adsorption: ionized organic or inorganic polymers, the following steps build a bridge between the colloidal particles due to the long circuit structure:

- Polymer dispersion.

- Transport the polymer to the particle surface.

- Adsorption of polymer onto the particle surface. - Binding between the polymer adsorbed particles with each other or with other particles.

2.4. Wastewater treatment by precipitation technology

Precipitation of calcium carbonate and metal hydroxide is the most common precipitation method in water treatment. The following is an example of how a water softening precipitate may be used:

• Use of lime: Ca(OH)2 + Ca(HCO3) = 2CaCO3 + 2H2O

• Use sodium carbonate: Na2CO3 + CaCl2 = 2NaCl + CaCO3

• Use sodium hydroxide: 2NaOH + Ca(HCO3)2 = Na2CO3 + CaCO3 + H2O

Metals in wastewater can be easily isolated by precipitating metal in the form of hydroxide. Optimal pH values for the most efficient precipitation of different metals do not overlap. Therefore, it is necessary to determine the appropriate pH value for each specific metal of wastewater to be treated. Besides, the precipitation process is also used in reducing SO42-, F-, PO43-.

2.5. Reverse osmosis technology

Techniques such as electrophoresis, reverse osmosis, ultrafiltration, and other similar processes are increasingly important in wastewater treatment. Membranes are defined as the layers that act as a barrier between the different phases. It can be a solid, or a gel (colloidal) swelling due to a solvent or even a liquid. The permeability of the compounds across the membrane determines whether or not membranes can be used to isolate them.

Definition of Reverse Osmosis (RO)

Osmosis is defined as the spontaneous migration of a solvent from a dilute solution to a concentrated solution through a semipermeable membrane. When the pressure increases the osmotic pressure on the solution side of the membrane as shown below, there is a backward flow, meaning that the solvent will move from the solution across the membrane to the clean water side. This is the basic concept of reverse osmosis. Thus, reverse osmosis can be defined as the process of filtering a solution through a semi-permeable membrane under a pressure higher than the osmotic pressure.

Figure 6. Mechanism of reverse osmosis (RO)

2.6. Ultra filtration - Micro filtration

Both ultrafiltration and reverse osmosis are pressure and dynamics-dependent processes that enable the membrane to allow certain organisms to pass through while keeping others out. The distinction between the two methods is that ultrafiltration is often used to isolate solutions with a molecular weight greater than 500 and a low osmotic pressure (for example, bacteria, starch, protein, clay, and so on). Materials with a low molecular weight and a high osmotic pressure are often removed using reverse osmosis.

3. Wastewater treatment by biotechnology

Biotechnology wastewater treatment method is applied to treat dissolved organic substances in wastewater as well as some other inorganic pollutants such as H2S, sulfite, ammonia, nitrogen ... on the basis of activity of microorganisms to decompose organic pollutants. Microorganisms use organic matter and some minerals as food to grow and develop. In general, biological treatment methods can be divided into 2 categories:

• The anaerobic method uses anaerobic group of microorganisms, operating in the absence of oxygen

• The aerobic technique involves a group of aerobic microorganisms that operate in an oxygen-rich setting. Biochemical oxidation is the process of microorganisms decomposing organic matter

To accomplish this, dissolved organic compounds in wastewater, as well as colloidal and small dispersants, must pass into the microbial cell in 3 stages:

• Contaminants from the liquid process are transferred to the surface of microbial cells

• Due to the differences in concentration inside and outside the cell, diffusion from the cell surface through the semipermeable membrane occurs

• Metabolism in microbial cells, energy production and new cell synthesis.

The rate of biochemical oxidation is determined by the amount of organic matter in the wastewater, the number of impurities in the wastewater, and the consistency of the wastewater flow into the treatment system. Hydrodynamic regime, oxygen content in wastewater, temperature, pH, nutrients, and trace elements are the key factors influencing the rate of biochemical reactions under certain treatment conditions.

3.1. Aerobic digestion

The three steps of the wastewater aerobics biological treatment process are as follows::

• Oxidizing organic substances: CxHyOz + O2 => CO2 + H2O + DH

• New cell synthesis: CxHyOz + NH3 + O2 => CO2 + H2O + DH

• Intracellular decomposition: C5H7NO2 + 5O2 => 5CO2 + 5 H2O + NH3 ± DH

Aerobic biological treatments may take place in both natural and artificial settings. The optimal condition for biochemical oxidation is produced in artificial treatment projects, resulting in significantly increased processing speed and performance. The artificial aerobic biological treatment method can be divided into three categories, depending on the current state of microorganisms:

• Aerobic biological treatment with suspended growth microorganisms is primarily used to minimize organic carbon-containing substances like activated sludge, ventilating lakes, reactor service interruptions, and the manure fermentation method. aerobic decomposition The aerobic activated sludge (Aerotank) process is the most common.

• Aerobic biological treatment with adhesion growth microorganisms, such as activated sludge, drip filter tank, high load filter tank, biological disc, and fixed membrane nitrification reactor.

Figure 7. Aerobic activated sludge tank (Aerotank)

3.1.1. Aerobic activated sludge treatment technology

Decomposition occurs in aerobic activated sludge tanks with suspended species when wastewater comes into contact with the sludge under constant aeration conditions. The aim of aeration is to meet the requirements for a constant supply of oxygen and to keep the activated sludge suspended.

The method is based on aerobic biodegradation with forced oxygen supply and a high density of microorganisms (2,000mg / L –5,000mg / L), resulting in a high and required organic decomposition load. The handling device would take up less room. The system's drawback is that it necessitates a lot of machinery and consumes a lot of electricity.

The concentration of dissolved oxygen in water from 2nd phase sedimentation tanks should not be less than 2 mg/l. The rate at which dissolved oxygen is used in the activated sludge tank is determined by:

• The F/M ratio is the proportion of food (CHC in wastewater) to microorganisms;

• Temperature;

• Microorganism growth rate and physiological activity;

• Toxic substance concentrations that accumulate during metabolism;

• Cell constituents;

• Dissolved oxygen content.

It is essential to comprehend the critical function of microbial populations in the design and operation of an aerobic activated sludge system. Just a portion of organic matter is totally oxidized to CO2, H2O, NO3-, SO42-,... by these microorganisms in wastewater, and they accumulate energy to turn into new cells.

In general, the microorganisms found in activated sludge systems include a wide variety of bacteria that coexist. When running an aerobic activated sludge system, the wastewater should have an SS content of no more than 150 mg/l, a petroleum product content of no more than 25 mg/l, a pH of 6 to 8.5, and a temperature range of 6 to 37 degrees Celsius.

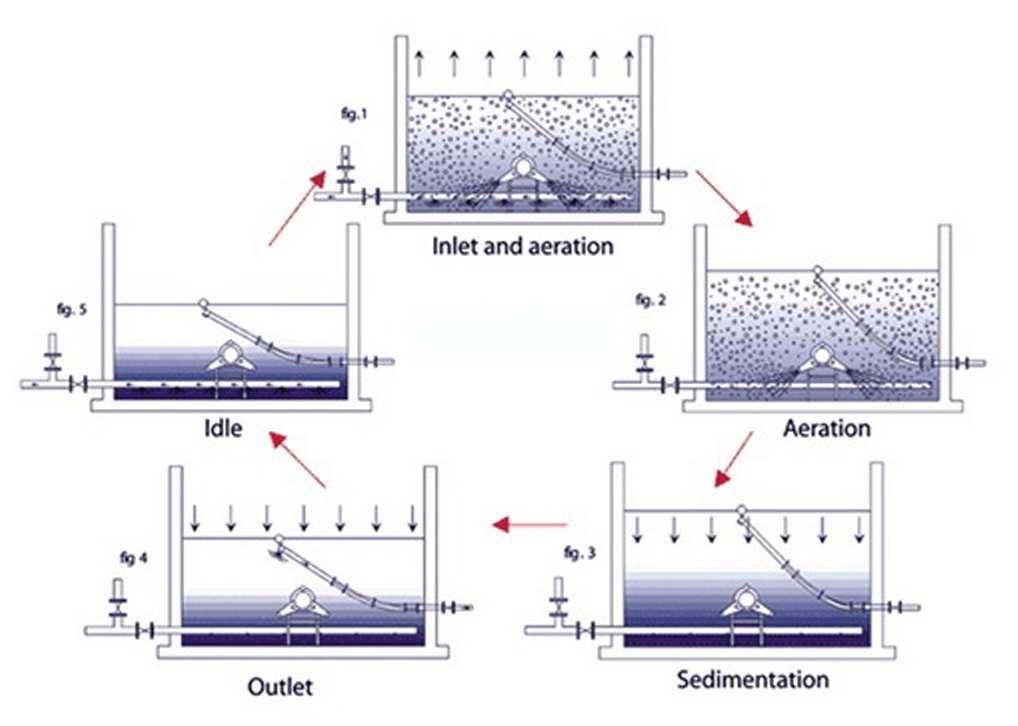

The Sequencing Batch Reactor (SBR)

Intermittent operation tank is a wastewater treatment system with activated sludge in a filling and draining manner. The process happening in SBR tank is similar to that in continuous activated sludge tank, only thing happens in the same tank and is done in turn: (1) - Filling; (2) - Reaction; (3) - Silence; (4) - Descaling; (5) - Stop.

Figure 8. Sequencing Batch Reactor

Biotechnology growth adhesion

The theory of action of the Active Sludge Tank with Sticky Growth Microorganisms is identical to that of the suspended microorganisms, except that the microorganism grows to bind to the contact content added to the tank.

Adhesion growth biotechnology is currently being widely used due to several Adhesion growth biotechnology is currently being widely used due to several outstanding advantages in treatment quality as well as reduced expenditure and operational costs. GREE successfully built and improved AFBR adhesion technology from FBR technology in 2010.

Trickling Filter

In wastewater treatment, a biofilter is a bioreactor in which microorganisms grow fixed on a layer of filter material. A water-permeable material with microorganisms on it is used in modern filtration tanks. Wastewater can seep or spill on this substance as it passes through it.

Filter material is usually crushed stone or block of filter material with different shapes. If the filter material is stone or gravel, the particle size ranges from 0.5 to 2.5 m, with an average of 1.8 m. Filter tanks with crushed rock material are usually round. A dispenser distributes wastewater over the filter material sheet. Filter tanks made of plastic filter material come in a variety of shapes and sizes, with heights varying from 4 to 12 meters. (1) Materials with vertical flow, (2) materials with transverse flows, and (3) diverse materials are the three most widely used plastic materials.

Microorganisms on the filter material layer can decompose organic matter. Organic compounds in wastewater can be adsorbed into a 0.1-0.2 mm thick microorganism membrane and decomposed by aerobic microorganisms. Since the membrane thickness of microorganisms grows and develops, oxygen is absorbed until the biofilm's maximum thickness is diffused. As a result, an anaerobic atmosphere forms right next to the filter material's surface.

Organic assimilation occurs as the film thickness increases, until they come into contact with microorganisms near the filter material's surface. As a result, microorganisms degrade intracellularly, are unable to cling to the filter material's surface, and are washed away.

Figure 9. Trickling Filter

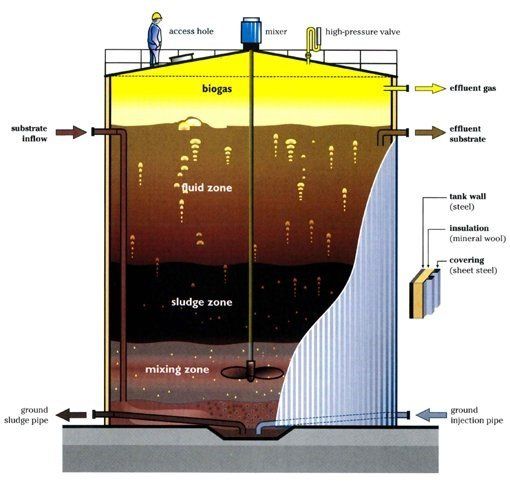

3.1.2. Anaerobic biotechnology

Anaerobic decomposition of organic matter is a complicated biochemical process with hundreds of intermediate products and reactions. However, in anaerobic environments, the biochemical reaction can be articulated simply as follows:

Organic matter =====> CH4 + CO2 + H2 + NH3 + H2S + new cell

Generally, anaerobic digestion occurs in four stages:

- Stage 1: Hydrolysis, circuit cutting of polymeric compounds;

- Stage 2: Acidification;

- Stage 3: Acetateization;

- Stage 4: Methaneization.

Organic wastes comprising polymeric organic matter such as proteins, fats, carbohydrates, celluloses, lignin, etc. would be circuit-cut to shape smaller, more easily biodegradable molecules throughout the hydrolysis process. Proteins are converted to amino acids, carbohydrates to simple sugars, and fats to fatty acids during hydrolysis reactions.

During the acidification phase, simple organic matter is further converted to acetic acid, H2 and CO2. The main volatile fatty acids are acetic acid, propionic acid and lactic acid. In addition, CO2 and H2O, methanol, and other simple alcohols are also formed during the cutting of carbohydrates. Methane-converting microorganisms can only degrade certain substrates such as CO2 + H2, formate, acetate, methanol, methylamines and CO. The reaction equations are as follows:

4H2 + CO2 => CH4 + 2H2O

4HCOOH => CH4 + CO2 + 2H2O

CH3COOH => CH4 + CO2

4CH3OH => 3CH4 + CO2 + 2H2O

4(CH3)3N + H2O => 9CH4 + 3CO2 + 6H2O + 4NH3

Anaerobic treatment can be classified into three types depending on the condition of the sludge: Anaerobic treatment with suspended growth microorganisms such as anaerobic contact, anaerobic sludge treatment with bottom up water flow (UASB). Similar to the anaerobic filtration process, the anaerobic treatment with microorganisms grows in the form of adhesion.

Figure 10. The structure of wastewater treatment tank applies anaerobic treatment technology

The anaerobic treatment tank technology

Organic substances in wastewater are converted to methane and carbon dioxide during the anaerobic wastewater treatment process, which takes place in the absence of oxygen. Anaerobic ponds or different types of high-load reactors may be used as anaerobic treatment systems.

Anaerobic lagoons are used to treat wastewater with a high organic matter concentration and a high residue content. The anaerobic lagoon's depth should be 2.4 m (8 ft), but it can exceed 9.1 m with retention periods varying from 20 to 50 days.

The process of stabilizing wastewater in the lake occurs under the combined effect of precipitation and conversion of organic chemicals into CO2, CH4, other gases, organic acids and new cells. The conversion efficiency of BOD5 can reach 70 - 80%.

Anaerobic biotechnology UASB

This is one of the most widely used anaerobic processes in the world due to two main features:

• All three processes, decomposition - sedimentation - air separation, are installed in the same structure;

• Generating sludge with a very high microbial density and a sedimentation rate much greater than that of suspended aerobic activated sludge.

Besides, as compared to the aerobic activated sludge process, the anaerobic biological treatment process using UASB has advantages such as:

• Operating energy demand is reduced.

• Excess sludge is minimized, lowering sludge treatment costs;

• Water can be easily separated from generated sludge;

• Low nutritional requirements should result in lower nutritional supplement costs;

• Capable of extracting energy from methane gas;

• Since anaerobic can be restored and usable after a time of inactivity, it is suitable for seasonal service.

The UASB (Up-flow Anaerobic Slugle Blanked) system was created from an anaerobic treatment system for wastewater with high organic pollutant concentrations. Because of all the following benefits, UASB has been studied in detail and widely used in the world in recent years:

• Although this organic decomposition load is heavy, the treatment system requires a limited amount of space.

• Low energy demand as a result of a shortage of oxygen supply.

• Energy-recovery capability.

In conclusion, the decomposition of organic compounds by microorganisms is at the heart of biotechnology wastewater treatment. The methods of biodegradation can be categorized as aerobic, anaerobic, or arbitrary depending on the quality of the air supply. To achieve a high biodegradation efficiency of organic contaminants, essential nutrients such as nitrogen, phosphorus, and probably some rare elements must be added. Because of the low operational and maintenance costs, biological treatment is used in a wide range of situations.

Posted by Stephen Nguyen

May 4th, 2021

Author: All information collected from many internet sources.